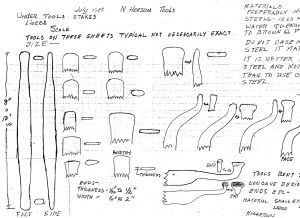

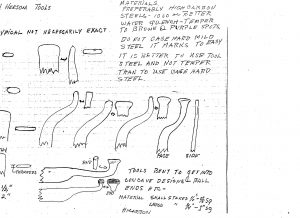

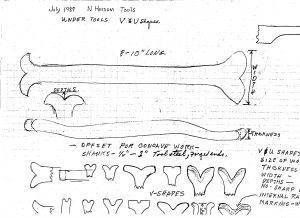

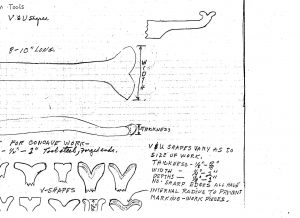

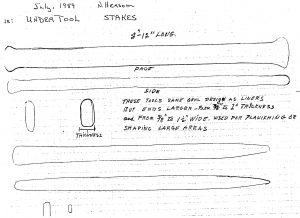

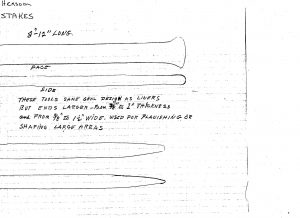

Repoussé X: Under Tool (Stake) Designs for Repoussé

This is a continuing series, consisting of the writings of French repoussé master Nahum Hersom. I have transcribed his words exactly, unless indicated by ((double parenthesis)).

The following pages are from 8-1/2″ x 14″ pages. However my scanner can only scan 8-1/2″ x 11″, so I have split the pages into two parts, i.e., 1A + 1B, 2a + 2B, etc.

Under Tools (Stakes)

((The following text is transcribed.))

Under Tools

Stakes: Made of tool steel ((a.k.a. high carbon steel)) and tempered to a brown with purple spots. Mils steel tools are ok for one time tools. Can be tempered with lye solution or Shaklee solution. ((As the latter methods of tempering can be dangerous to your health, I do not recommend attempting to use chemicals to harden steel.)) Best for forging forming tools, grapes, etc. Spring tools for power hammers.

Case hardened tools will die mark where tempered tool steel will resist this. ((Here again, I do not recommend case hardening either, as the chemicals can be very dangerous to your health. Find a commonly available high carbon steel such as W-1, learn its properties, and then you will not be concerned with alternative hardening methods. Get on with the business of repoussé.))

When welding tool steel, i.e. ball bearing to mild steel shanks, use stainless steel welding rods. I heat to dull red and let cool. Removes welding strains. Sometimes I cool tools when at black heat in oil, otherwise, do not temper. Lots of times they crack.

After forging ends of under tools, anneal and shape, file, grind, etc. When using sanding belts, which usually are better for shaping tools, start with a medium grit belt, not a very coarse one. Coarse belts, like coarse grinding wheels, put in deep scratches which take a lot of time to remove. If you use a file to shape end, again, use a medium tooth file and then a fairly fine one. Afterwards, use shop roll paper ((fine grit emery cloth)) under file to remove deep scratches.

When using a sand belt, using the directional scratches made by belt, first one way, then across it, helps to define the shape of tools. Also, watch carefully the shape of the tool, to keep it symmetrical on contoured surfaces that you want. It is easy to distort the shape, especially on intricate and compound curves. Sometimes, the true shape is hard to define without a keen eye and this contrast crossing grinding belt lines is a good background to look against for corrections as you work on tools. Curve of ends of tools to correspond to radius of hammered piece – Tools to fit design, size and shape for more accurate convex or concave work.

By wrapping leather over end of stake, tool marks can be avoided on some work, especially if the piece being worked is turned over, as you work both sides on the same stake. On some jobs where soft metals are used, wood under-tools eliminate eliminate under-tool marks.

((End of this section))