Blacksmith/Client Relationship I

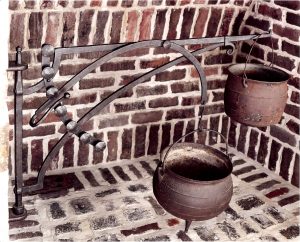

Photograph by George Lottermoser.

The following information may be useful for the blacksmith, as well as for those who wish to commission a blacksmith for a future project.

Based on recent dealings with a current client, I would like to take time out from discussing images of ironwork to discuss the relationship the blacksmith should have with his/her clients, and the potential for problems, and how to avoid these problems.

Today I will address a matter foremost on my mind, and that is of design.

Typically, I produce the design for the piece I am to make for my clients. Occasionally, as with the current job, the design concept is presented by a third party, in this case, the client’s architect.

In the first meeting with the client, I always establish the groundwork, or the order and basis in which the project will develop on this end. Before I touch pencil to paper for a design, I require 10% of the perceived value of the project, i.e. a $15,000 job would have a $1,500 design fee. My minimum is $400.

Though a design may be already established, you still need that 10%, as more often than not, there will be many revisions to be made so the rendering made by another accommodates what you, the blacksmith, can actually construct. Though an architect, or anyone else, (shy of another blacksmith), may have somewhat of an understanding of the function of the piece, and even an idea of the forging process, there will always be revisions.

Simply put, they are not building the piece, so they have no idea as to how you typically approach the particular project. This is not to say these individuals are lacking in design, rather they are usually unfamiliar with how we, as blacksmiths, make things.

Remember that our trade is no longer common, nor is it taught in school. Most folks will not know our mechanical language, which speaks of collars, rivets, forge welding, mortise and tenons, half laps, etc. An all important part of your job is to educate the client, and the designer about the general aspects of forging. After all, it is what separates us from the more common fabricator….mind you there are some fine fabricators out there.

Therefore, you must take it upon yourself to be correspond graciously and often, documenting everything, doing your utmost to keep the the client, architect, and yourself clear on every aspect of the project.

This will mean many e-mails, phone calls, sketches, and drawings on your part as the smith.

Remember also that every and all changes must be validated by the client, not the designer alone. That includes you, if you are the designer, as even the simplest alteration may become an issue when it is all said and done. By that time, it may be too late, and may require altering the project at your expense.

Design Conception

When a client inquires about a project, you need to know several initial things:

1.) What does the client want?

2.) What is the function of the project?

3.) What is the budget?

4.) What is the deadline?

5.) What is their concept of design?

Get to the root of things right away. You do not have time to be on the proverbial “wild goose chase”, and you do not want to waste a potential client’s time either.

For example, if the client is interested in a simple, functional railing, they do not need a blacksmith to do the job. I did not become a blacksmith to make basic functional railings. Plus, I am a better blacksmith than I am a welder, which is the forte of a fabricator. You may point the client to having the railing fabricated by someone else, as a fabricator will typically have a more reasonably price for the simple job. I refer many folks to a fine local fabricator, Dean Derge Ironworks, who has a fine track record.

This is not to say you cannot sell the folks who wish for basic, functional work on the merits of finely forged ironwork. If you get the sense that they might be a candidate, then discuss the differences between a forged and a fabricated piece. They may come to understand that you can provide more than just a functional railing, designed and executed in a fashion that stimulates the eye.

However, if their budget suggests otherwise, and they will not entertain a higher budget, recognize that you are wasting their time and as well as yours.

Make an Appointment to See the Client.

Once you establish the basic premise of what you can provide, and how you do business, then the next step is to take a visit to the job-site. This allows you to see the environment in which the piece will reside, and also gives you valuable time with the client.

A discussion of design and function is essential. Bring a portfolio of your best works, and have them page through it. No matter what it is they want, show them all your work…. gates, railings, furniture, etc. Ask them to tell you what features they enjoy in the works seen in the portfolio. Take notes about their comments. When they are through reviewing your work, you should have a fine idea of their tastes, likes, and dislikes.

Also, ask the prospective client about their work, hobbies, and family history. You may entertain the notion of incorporating some aspect of these into the design.

Remember also that some clients may not have a clear understanding of the function of the piece, and also the relationship to the architecture, or how the piece will be installed. You should be the expert in this regard, voicing your considerations and concerns up front.

By all means, ask questions, and then listen intently to the client, all the while taking notes.

If the job-site has yet to be built, you also need to be in close contact with the masons, carpenters, electricians, and the contractor, providing them with as much information regarding your product as possible. Not only will these individuals appreciate this, you will too, as when installation day arrives, you will be all the happier when the installation goes without a hitch.

Get the names, e-mail addresses, and phone numbers of all related individuals, whether you feel you will need them or not. When you need to contact them , you will then be prepared.

Deadline

If the deadline is not realistic, be up front about this. You do not want to dissappoint your client by being late, especially if they are depending on your work being installed by the time they entertain their friends or clients. Most of the time, if you explain your schedule, the client will understand, and allow you the time needed. Never say “I cannot do it by that date.” rather, give them your own projected completion date, and let them decide.

If however there is an impass on deadline, then you need to again be honest with yourself…….can you adjust to their schedule? This may mean longer hours in the shop. In this case, I personally need to adjust my pricing so I get compensated for the extra effort. Again be honest with the client by letting them know you need to inflate the costs to meet their deadline. This is not a method you should use simply to inflate your prices.

Usually, my clients do not have a clear concept for the design, leaving that entirely to me. If they do have an idea, listen intently. You are working for them, and you should try to address their wishes.

On the other hand, if they seem to be off base, you need to discuss in a manner which will not discourage them. Remember, other folks will see your work, and you cannot afford a reputation for producing a piece that does not fit the style of the environment, or misses the boat functionally.

The drawing of the design you present should be to scale, should reflect all aspects of construction, i.e. mortise and tenons, rivets, collars, etc. You may need to do supplemental drawings to show details.

The quote should also be prepared, outlining the bar-stock sizes, dimensions, finish, price, down payment, and any progression payments, etc.

Once the design is completed, I make a fine copy, and then frame it.

In another installment, I will address other aspects of dealing with your client.

…….Dan Nauman

“Every problem has a gift for you in its hands.”…….Richard Bach, Author

3 comments to “Blacksmith/Client Relationship I”

Michael E. McMahon - January 2, 2010

I really like this blog. Please continue the great work. Regards!!!

Greg Meeker - February 3, 2010

Students always make easy things hard.

Richard Bach, author

Great blog! Thanks for all your work for ABANA, and the Lord.

bighornforge - February 5, 2010

“Amen!”

…….Dan