Repoussé II: “Sheet Metal Punches”

With repoussé artist Nahum Hersom’s passing a few months ago, I decided to share some of his writings with others that might be interested. This is the second installment.

Note: Words in parenthesis are added, or rephrased for better understanding.

Sheet Metal Punches for Holes

Holes can be punched through sheet metal with a shaped punch over a hardwood block, preferably (wood) with close grain. Use end grain for punching. Blocks can be fabricated of 1″ x 6″ pieces of hardwood glued together. Bandsaw surfaces (so they are) flat. Grind ends of punches (so that they are) oversized, as holes deform. When hammered flat, (the) hole size decreases.

(Note: To save on wood blocks, when the surface of a wood block fills up with sheet metal slugs from punching, cut a layer of the wood off, and now you have a new surface for punching.)

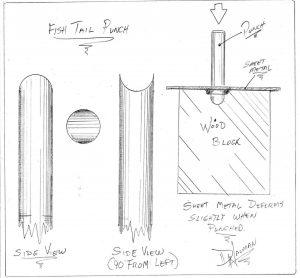

Holes can be square, round, triangle, diamond-slots, star, scalloped, round, or any combination of shapes, but cutting edges must be in the fishtail shape so as to have two edges to start shearing action. These do not have to be more than 1/16″ deep for most lighter sheet metal work. For heavier metals, the fishtail shape should be as deep as the metal is thick.

Any shape punch can be made, but the cutting edge must be ground to a “fish-tail” shape to facilitate shearing action as the punch goes through the metal. (See image below.)

(To better convey the fishtail shape, I have grossly enlarged the shape above. It need only be 1/16″ deep for most thinner metals, i.e. 22, 20, and 18 gauge.)

Use (a) flat faced hammer head (to strike the punch.) Use high carbon steel or steel alloys (to make punches.) Nahum prefers water quenching (high carbon steel.) (When tempering,) draw cutting edge to light brown.

To punch 3/4″ slots through heavy sheets of 1/8″ and (thicker,) drill a slot sized hole at the end of each end of the slot area (into the sheet.) Put a piece of iron the width od the slot into the bottom-side of the vise jaws to hold the jaws in position. (Then) put a slot sized fishtail punch in the two holes. Strike with a heavy, flat-faced hammer and punch out the slug. The edges of the vise jaws (act) as a bottom die. Grind off punch burrs and file hole to (the) finished size.

Most (of Nahum’s) punches are approximately 4-1/2″ long with tapered tops (striking surface.) (This) length is about right for (a) good grip and punch control. (Nahum likes to forge his punches square when he needs rotary control, with a good radius on corners.) Round punches can be made from round stock.

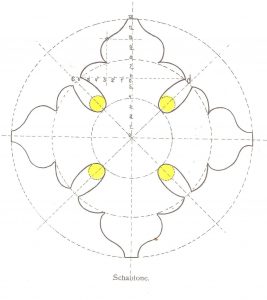

(I have inserted a pattern here to show you an application for using a fishtail punch. The yellow shaded areas should be punched out before cutting the pattern. Doing so will prevent “X” or “Y” cuts in the “gores” from the shears or the band-saw. Punching also produces a nice radius in the gores, which are tough to cut with shears, band-saws, etc.)

Arabs and Hindus use asphaltum under brass for support when punching lamp parts. Asphaltum has filler to stiffen as needed. Punch holes with lead block under (the) sheet metal if needed. Re-melt lead, remove the punch slugs, and re-pour to block shape.

Punches-Non Shearing

Tool cutters are chisel shapes of various widths and shapes used for making design lines in metal, but the edges are rounded. The width of the rounded edge determines the width of the line. Much forge work uses these style punches for design and definition.

In repoussé, this style punch is used many times with a lead block to enhance or make corrections in designs.

Ball punches: (These are) used with (a) lead block to raise designs as per Mexican tin work lamp embellishment (and) sconces. Use (them) with dopping block (a block with a hemisphere depression) to make (a) half hemisphere.

Hand veiners are like tool cutters, but have wider edges and widths to shape or reshape veins, using a lead block underneath.

Punches for special work generally have edges rounded and polished to fit whatever shape is needed to get into corners, contours, etc. Sharp corners cut thin sheet metal and can spoil a job, (by)leaving sharp cutting shape corners where a nice round or contoured shape is needed.

Mexican Tin Work

-Rubber blanket under tin.

-90 lb. roofing or lead sheet, or end grain of wood: pine or soft maple.

-Floral design, lamp shades, etc.

-Retablas, chisel cut flowers.

-Colored lacquer for color.

Transfer Punches

(Nahum) uses these to get rounded corners, (or to) drill holes where (he) needs clearances, etc.

(End of this installment.)

….Dan Nauman